請用 Wechat 掃描台灣精品QRcode 或 搜尋ID: TaiwanExcellence

The world's first PDLC dimming film also has the function of green building materials. It can be used in floor-to-ceiling windows/curtain walls to enjoy the privacy of PDLC. It also takes into account the high-level functional UV blocking + IR blocking properties,which can reduce the indoor temperature by 2oC. In summer,it can save 13~18% air-conditioning power consumption.

The smart PDLC film with optoelectronic properties has the switching function of transparent when power on and opaque when power off. The smart glass made of smart PDLC film has both transparency and privacy,and can be widely used in architectural spaces.

The PDLC 97 Ex(GR) film is a UV exposure process in the manufacturing process,and the use of none solvent is a green process,avoiding environmental pollution,and the concept of environmental protection and sustainability; PDLC 97 Ex(GR) film has passed many third-party verifications to ensure that without toxic substance residues (REACH/RoHS).

About BenQ Materials Corp.

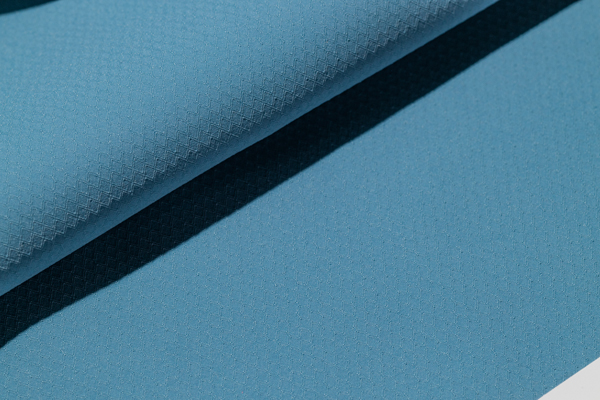

Founded in 1998, BenQ Materials started with the development and manufacturing of optical storage products. Our ethos of “Live with Innovation” drives us forward in the pursuit of materials-science solutions through the cross-application of materials and six core manufacturing technologies. We leverage our expertise into developing four major application categories: functional films, advanced battery materials, medical, and fabrics. Today, BenQ Materials is a premier supplier of display-materials solutions and the proprietor of several leading brands in various industries. Headquartered in Taoyuan, Taiwan, the company has production sites in Taiwan (Taoyuan, Longtan, Yunlin) and China (Suzhou, Wuhu) as well as a number of sales and service offices in Taiwan, China and Malaysia.

As a leading manufacturer of medical sterilization packaging in Asia, SIGMA has 40+ years of industry know-how. Vertically integrated with BenQ Materials, we leverage the Group’s resources to propel innovations to new frontiers. We offer end-to-end services for medical device manufacturers, including material selection recommendations, comprehensive material testing, sterilization packaging, and final transportation. Our product verification and process validation procedures adhere strictly to ISO 11607 standards, and our lab quality management system complies with ISO 17025. Through rigorous sterile packaging inspection covering sterilization services, sterile barrier integrity, packaging strength, material properties, compatibility, and stability testing, we ensure our customers' peace of mind.

Contact info

Tel:03-3748800#2754

Fax:03-3619900#2754

Email:Penny.Tsai@BenQMaterials.com

Tel:03-3748800 #2882

Fax:03-3619900

Email:frances.peng@benqmaterials.com

Email:Richard.Neo@BenQMaterials.com

Tel:03-3748800#2881

Email:Jeannie.Cho@BenQMaterials.com

Tel:03-37488000#2754

Email:penny.tsai@BenQMaterials.com