請用 Wechat 掃描台灣精品QRcode 或 搜尋ID: TaiwanExcellence

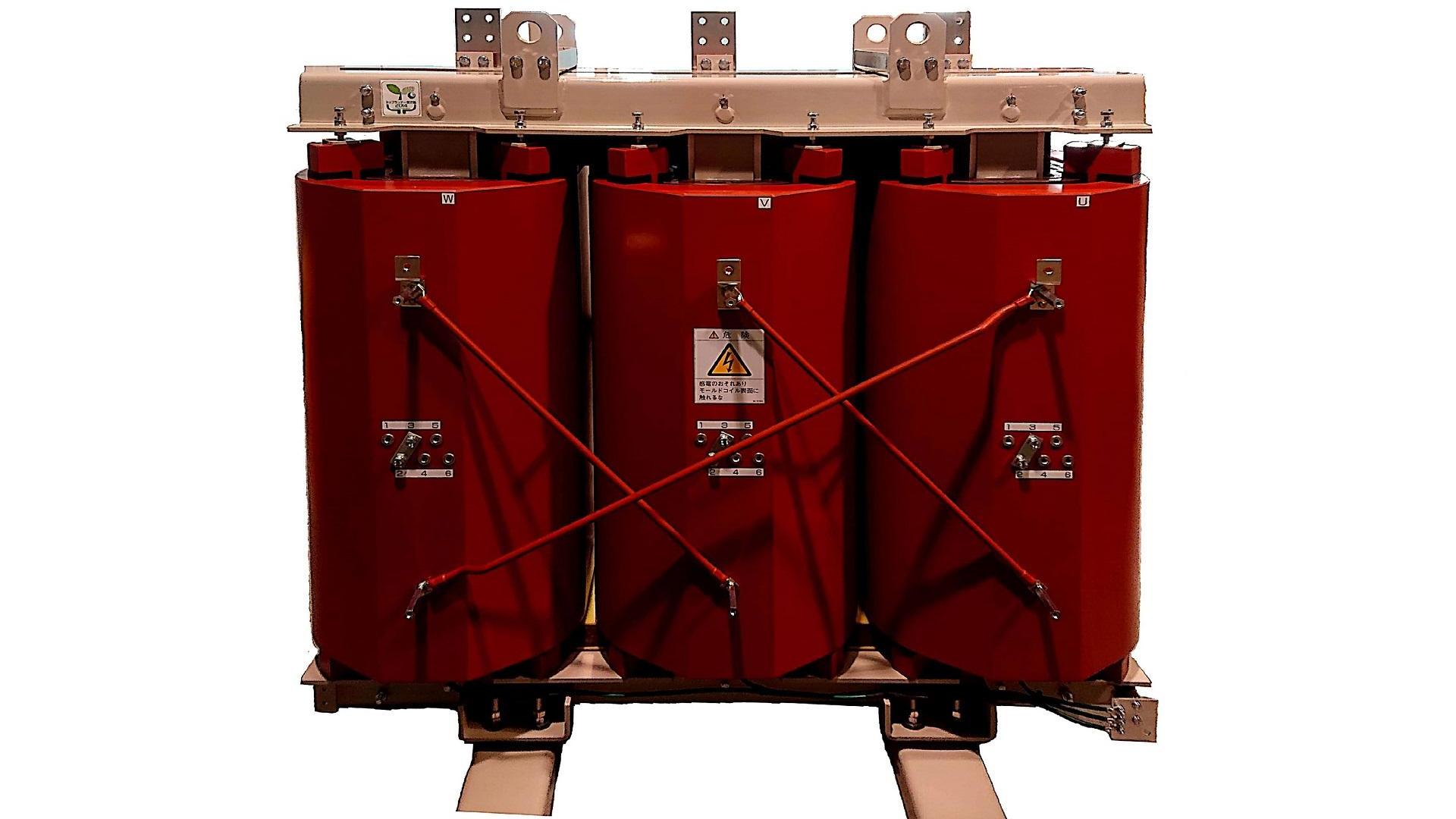

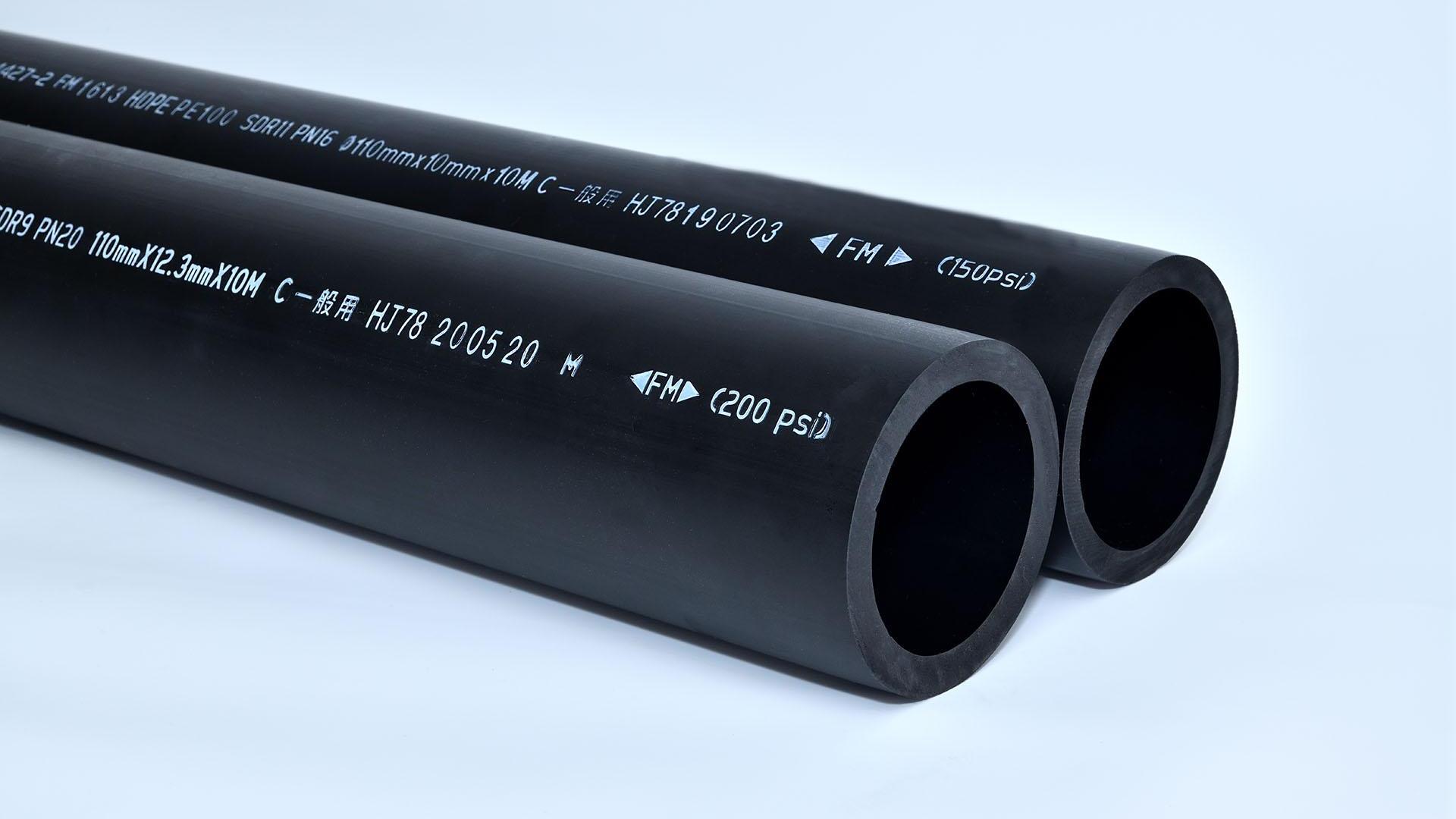

Based on the foundation of quality assurance established by ISO certification, OHSAS certification, CNS certification, and TAF national laboratory certification, Nan Ya has applied for the FM certification of FM 1613 underground fire-protection PE pipes with higher quality standards and stricter requirements. Various improvements and enhancements in raw materials, equipment, molds, test equipment, etc., officially passed FM certification in 2019, becoming the first company in Greater China to pass FM 1613 certification. Nan Ya's high-quality FM-grade PE pipe has the advantages of earthquke resistance, the best corrosion resistance, and excellent ductility. Long-term use will not cause the pipe wall to crack. The service life is more than 50 years. It can ensure the safety, usability, and durability for underground fire-protection piping.

About NAN YA PLASTICS CORPORATION

Nan Ya Plastics Corporation was founded in 1958. The four main product categories of the company are plastics processing, plastic materials, electronics materials and polyester product. Nan Ya Plastics Corporation believes, based on public information released by its competitors, that it 's the world's largest manufacturer of secondary plastics in terms of production capacity. It's also a leading manufacturer of polyester fibers and copper clad laminates of the electronic materials in the world.

Nan Ya Plastics Corp. was founded in 1958, and its industry has expanded into the fields of plastic processing, plastic raw materials, electronic materials and polyester fibers. Adhering to the two founders, Mr. Yung-Ching Wang and Mr. Yung-Zai Wang, the spirit of diligence and simplicity, perfectionism, sustainable operation, and dedication to society, we are committed to improving operating efficiency and quality. We also continue to invest in education, medical care and caring for disadvantaged public welfare undertakings. To fulfill the responsibilities of corporate citizenship. At the beginning of its establishment in 1980, the pipe factory had a monthly production capacity of 5,500 tons. In 1995, the pipe formula was changed from lead to tin. In 1997, the monthly production capacity of pipes increased to 19,042 tons. The rigid pipe factory began to build a virtual entity integration system in 2016, and the manufacturing process was integrated into automated monitoring

Contact info

Tel:02-27122211#5767

Fax:02-27178512

Email:classic@ficnet.net

Tel:02-27122211#5626

Fax:02-27178533

Email:cable@npc.com.tw