請用 Wechat 掃描台灣精品QRcode 或 搜尋ID: TaiwanExcellence

Product features

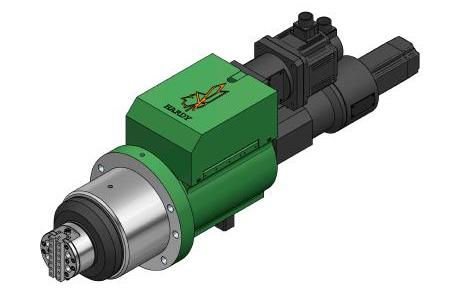

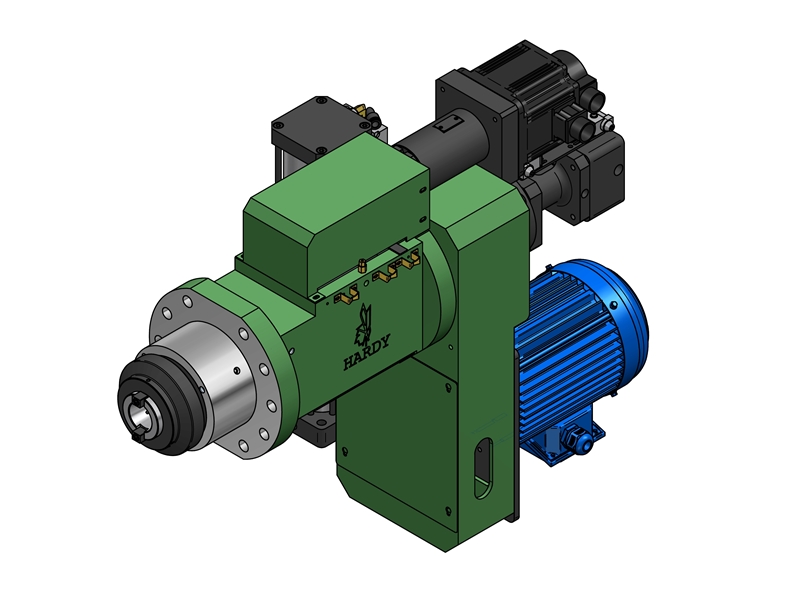

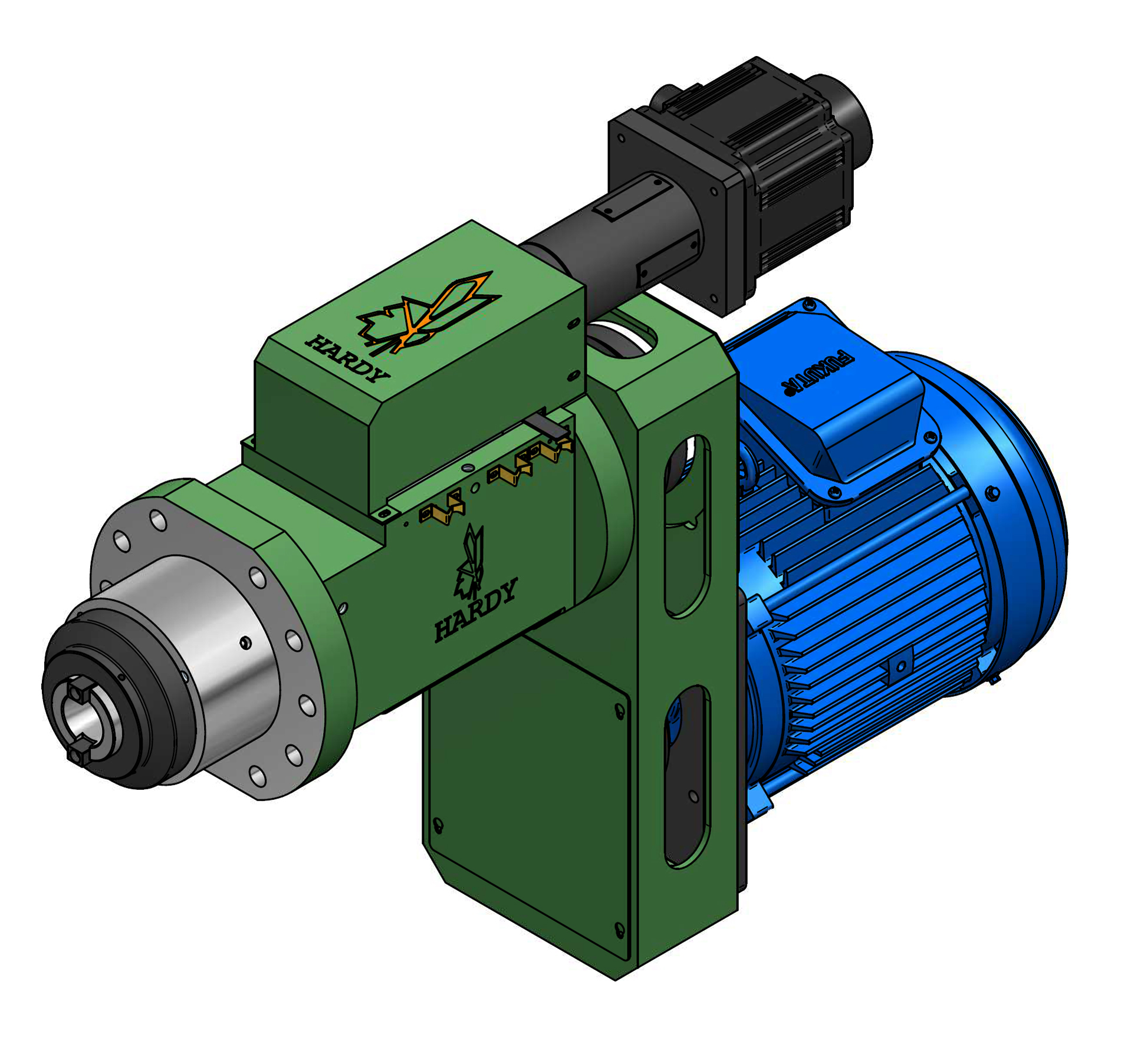

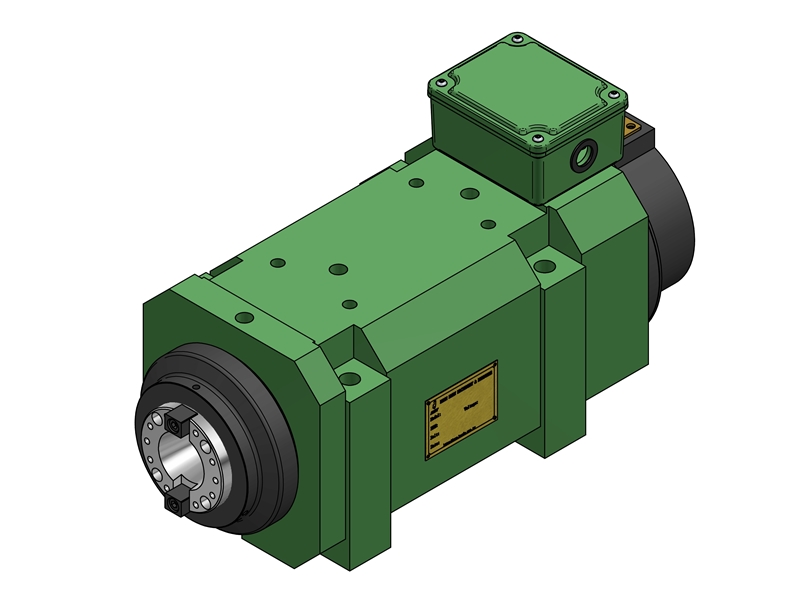

1.Body is made of FC30 casting & has been removed the internal stress after tempering treatment, to have the best rigidity and vibration-absorbing capacity and ensure the machining accuracy.

2.The spindle is made of SCM440 which is high tenacity alloy structural steel, with high purity, small decarburization, low cold heading cracking rate, stable heat treatment quality, uniformity of hardness and good hardenability.

3.When installation, the body bottom keyway as fixed position to mount on customer’s machine and has been grinded to ensure the center consistency.

4.Adopted ballscrew and servo motor driven, the servo system does continuous processing of high frequency to show the machine’s effectiveness and speed. It does multi- step stroke control by servo motor with driver thru coupling to connect ballscrew.

5.Facing application in coordination with LM smoothly sliding, and ballscrew feeding transmission to ensure position accuracy.

Marketing feature:

1.Market includes China, India, Thailand, Indonesia, Mexico, South Africa, Turkey and Europe. Product field includes metal accessories, automotive manufacturer and machine automation design & manufacturer.

2.The Indians-HARDY logo, simple pattern with uniqueness & high quality. It deeply in supply chain, retailers & customer’s mind. Customer easy to identify our logo represents profession and fully satisfied with customer’s request. Each year brand management fee is 3.9-5.3% of turnover. Using business trade platform, include machine monthly magazine, famous exhibition (ex: Europe EMO, America IMTS, Japan JIMTOF, and Taiwan TMTS..), internet & Baidu keyword advertisement marketing, update regularly our website www.hardy-tw.com products information, to upgrade product exposure and international visibility

3.Domestic and international retailers set up in 8 areas, 2015 turnover is NT 164.8 million, estimated turnover in 2016 is 180 million, can achieve 220 million in 2017, the growth rate is 9.9-22.2%

About HANN KUEN MACHINERY & HARDWARE CO., LTD.

Hann Kuen Machinery & Hardware Co. Ltd is a professional manufacturer of Drilling, Tapping, Boring/Milling spindle units, slides with servo and hydraulic types and machinery accessories with nearly 30 years of experience. Hann Kuen offers range of product specifications to meet the customer requirements and special customization products are also accepted.

Product casting material is FC30, stress relived for the deformation-free performance, high precision and maximum stability. The bearings in spindle are made from Japan and Germany, Hann Kuen maintains the accuracy strictly under 0.003mm.

Hann Kuen aims to offer quality products and efficient service in flexibility to our clients in different needs. “Innovation, Quality and Service ” are the principles that Hann Kuen holds highly.

Hann Kuen Machinery Co., Ltd. was found by manager Mr. Benson Chiang since 1985. Benson was born in a traditional family and grew up watching his father working with the sheet metal business. Not only he discovered a great interest in machinery fields which influenced by constantly seeing and hearing from his father getting the jobs done, but also has a strong curiosity in machine tools which was led him into machinery field in college major. Benson opened his first own shop named Hann Kuen at Jian-Kuo market in Taichung after he invented his first product mist coolant system after few year development. In order to start his own brand and image to the market worldwide, the name “HARDY” with an Indian head was established which describes a strong quality product on the symbol. The brand was sure impressed and engraved in the local and oversea markets. The image of Indian warrior HARDY logo becomes well-known in the markets which explain its definition to worldwide customers.

Contact info

Tel:+886-424860602

Fax:+886-424860605

Email:hann.kuen@hardy.com.tw

Tel:04-24860602#282

Fax:04-24860605

Email:hann.kuen@hardy.com.tw