請用 Wechat 掃描台灣精品QRcode 或 搜尋ID: TaiwanExcellence

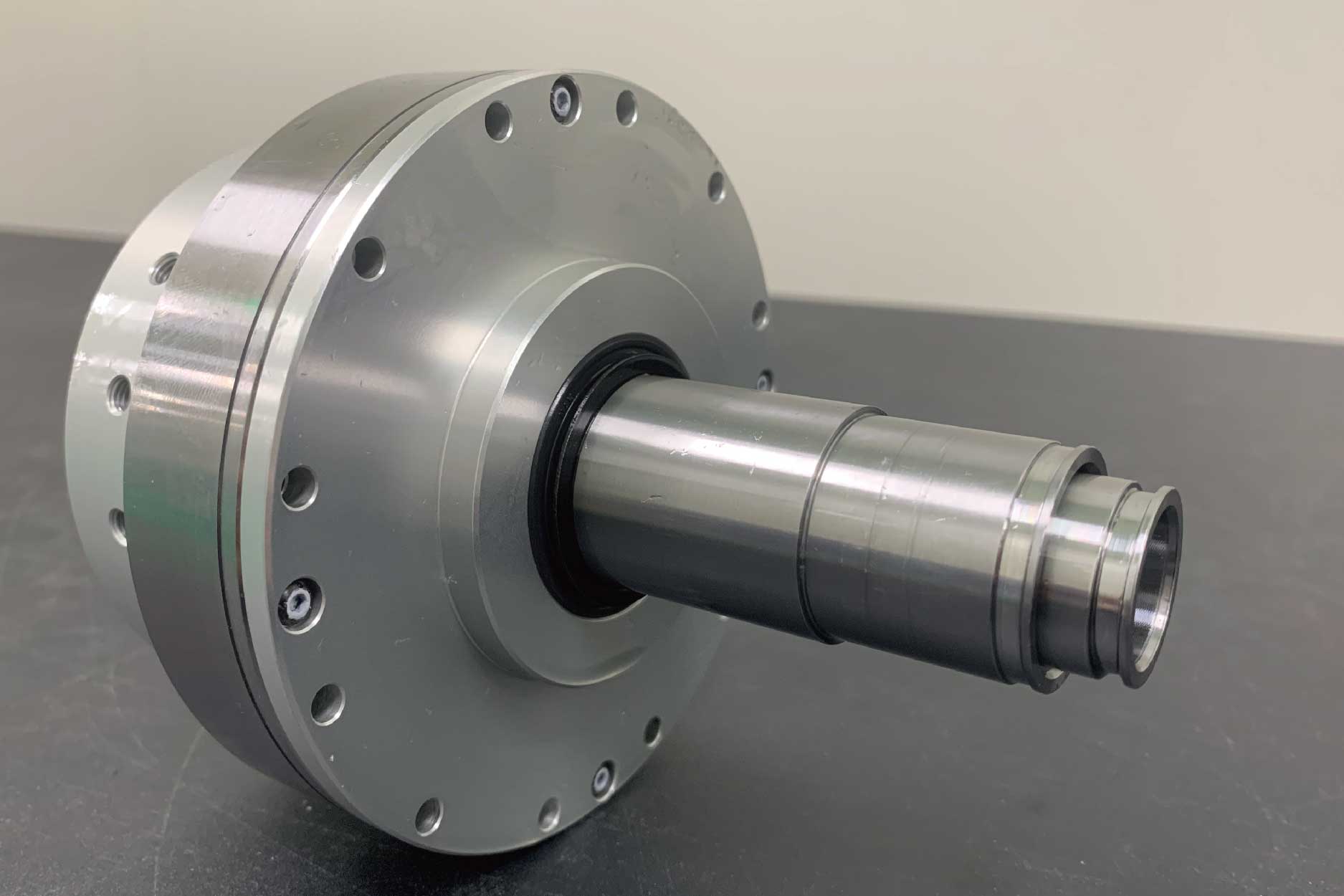

1.Product technology: Through the application of aluminum alloy material, it can greatly reduce weight and improve heat dissipation effect, introduce high temperature and high internal pressure oil seal, improve oil leakage protection at high speed and high temperature. 2.Innovative intelligent bonus: Through high precision and lightweight harmonic reducer and frameless motor, driver and sensor highly integrated, can form an integrated joint module product. 3.Industrial application value: corresponding to different industrial types of robots or automation applications, the use of joint module reducer, can flexibly form robots or automation systems that meet the needs of the industry.

About MAIN DRIVE CORPORATION

MAIN DRIVE Corporation was established in October 2018, specializing in the production of robot joint modules and harmonic speed reducers. With the key technology from Industrial Technology Research Institute (ITRI) in Taiwan, coupled with its R&D capability in computer analysis and design (CAD/CAE), the Company can design customized specifications according to the requirements of customers. The main functions of its products, such as angle drive error, meshing backlash, service life and efficiency, are superior to the performance of international large plants. With features of “high precision, high load carrying capacity, small size and stable drive”, the products are mainly used in multi-axis joint robots, collaborative robots with medium and low load, and various automatic equipment.

Main Drive Corp. was founded in 2018 with the goal of popularizing harmonic reducers. We aimed to make this key component more accessible to Taiwanese companies and startups focusing on automation applications and robot design, thereby enhancing Taiwan's domestic capability for autonomous development of harmonic reducers. What sets Main Drive Corp. apart from other reducer manufacturers is its early adoption of CAE tools for simulating application scenarios during product development. We also developed our own gear simulation software to optimize transmission efficiency and accuracy. Additionally, we utilize special testing equipment and experimental methods to ensure product stability and longevity.