請用 Wechat 掃描台灣精品QRcode 或 搜尋ID: TaiwanExcellence

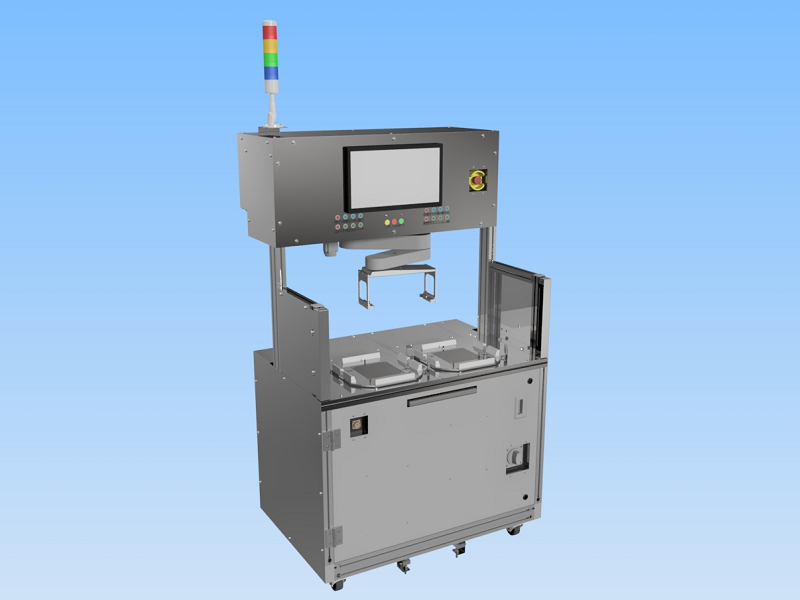

ITS has two amazing features. One is quickly recover system which can locate rapidly, and the other is quick coupling of signal circuit which can be easily dismantled as ITS is disassembled.

ITS is composed of various frames modules and lightest Scara robot that both of can be freely combined due to customer demands, quantity of ports, and load of Scara robot. In addition, the thickness of Scara robot is only 200mm, which is the lightest robot of the same industry in Taiwan. Last but not least, CHIFF Scara robot has passed EN ISO 10218-1 certification.

In response to the different needs of semiconductors, CHIFF offers the customized products like diversified module and logistics handling solutions. We are the equipment manufacturer for semiconductor wafer manufacturer in Science Park. Besides, we positively participate relative semiconductor organizations to get the latest information to improve our knowledges and skills.

About CHIFF TECHNOLOGY INC

- CHiFF Technology Inc. aim to provide state-of-the-art solutions in semiconductor wafer manufacturing for productivity reinforcement.

- Provide custom-made solutions via design and technique support in the field of Fab automation system, material handling.

- “More than HW” & “Operation Innovation”, we provide not only custom-made HW device, but also professional consultant service via the rich domain know-how; to upgrade to higher operational efficiency era.

- Added value to Wafer yield gaining through less human FOUP/POD/Cassette handling.

“The road of challenges is endless, and it is unregretful for me to start my own company.”, said Kuo-Hsiang Hsu.

For sixteen years working in TSMC, Kuo-Hsiang Hsu has found that still many problems to be solved if the semiconductor factory is to be fully automated. Such troublesome issue inspires Kuo-Hsiang Hsu to start up his business.

With experience, specialty, and being proud of independent research and development, Kuo-Hsiang Hsu has established a professional team which dedicates to amplifying limited space in fab. By installing equipment and improving space usage, it sharply increases wafer’s access speed, energy transmission, and production efficiency.

For eight years devoting to research and development, CHIFF Technology Inc. has expanded into the international market and become number one in market share in Taiwan and number two in global in the field of wafer stockers manufacturing.

“CHiFF Technology Inc. is established for fab solution.”

CHiFF is not only the equipment supplier for semiconductor wafer manufacturer but also the best partner for customers to find solutions to the fab problem. With well-experienced on manufacture and design capability on precision machinery, CHiFF wish that we’ll become “The Chief” of automated equipment manufacturer

CHiFF improves fab equipment level from “made in CHiFF” to “intelligent manufacturing” in CHiFF