请用 Wechat 扫描台湾精品QRcode 或 搜寻ID: TaiwanExcellence

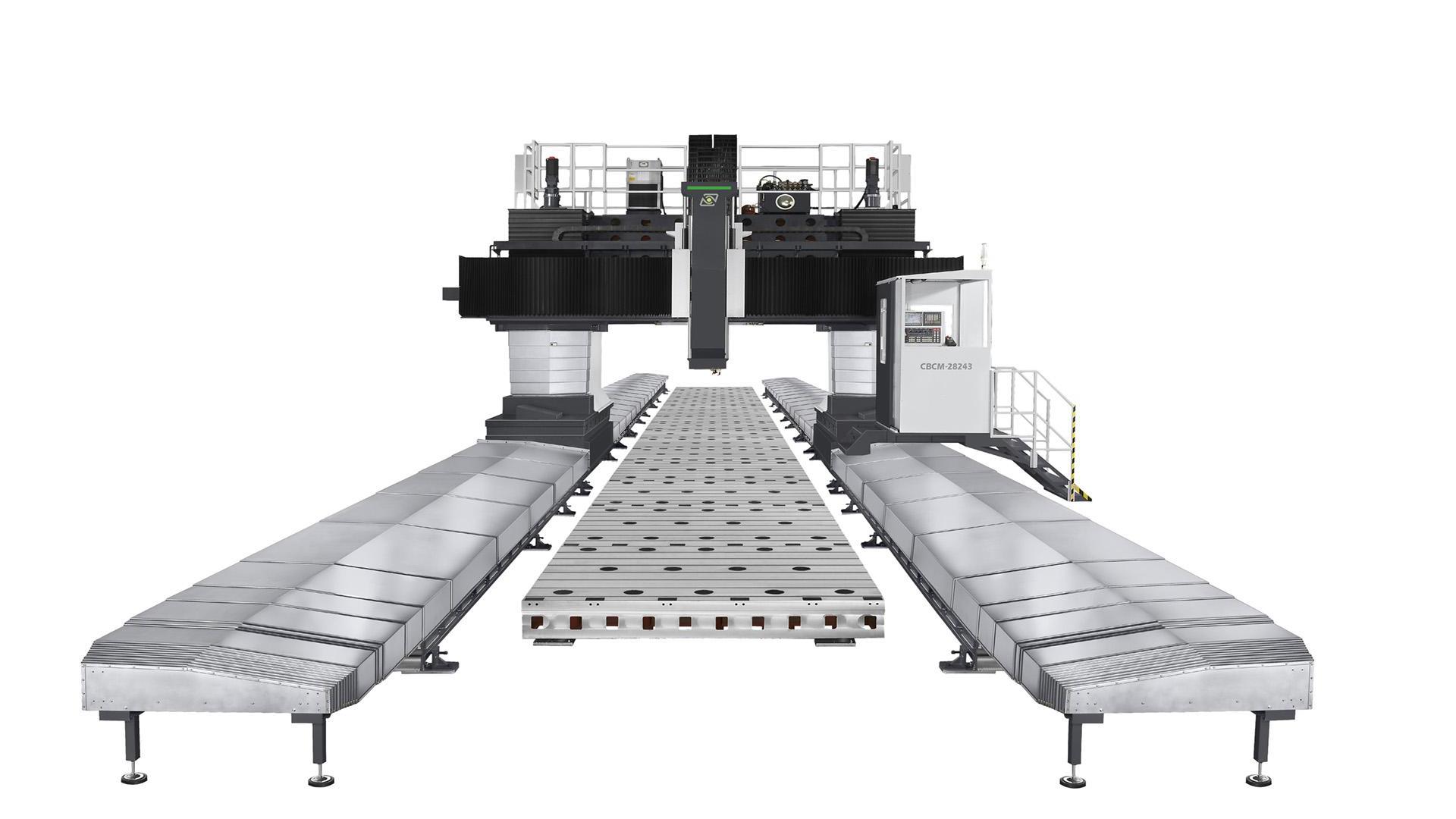

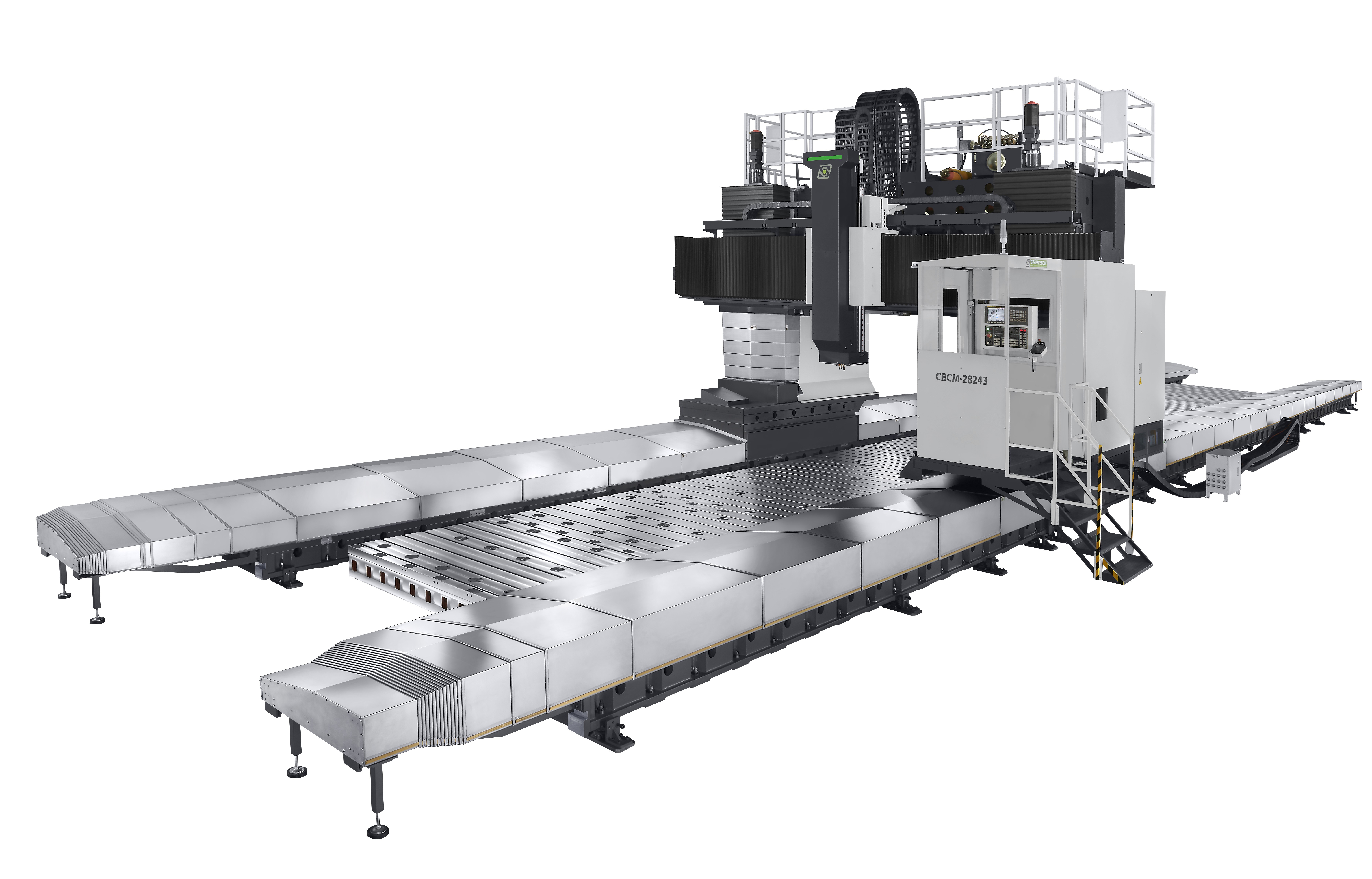

1. BCM Series adopts W axis and Z axis of box way design move simultaneously and process with a 5-face milling head.

2. W axis comes with multi-brakes control system and pressure-holding mechanism to ensure minimum backlash compensation when W axis moves.

3. The patent of crossbeam clamping mechanism is designed with hydraulic braked and full-travel wear compensation to perfectly maintain accuracy when moving.

4. The W axis and Z axis of BCM can be processed at the same time. For extra large and long workpieces or with large height differences, compared with fixed beam models that require two-stage processing, BCM can save a lot of processing time, as long as BCM series can meet the diversified continuous processing.

5. The X axis is smaller 30%-40% than the same travel; the footprint is reduced by 30-40%.

关于 STARVISION MACHINERY CO., LTD.

PURSUE EXCELLENCE. STRIVE TO DO BETTER. Starvision carries 20 years of professional experience in R&D, assembly, quality control and marketing Double Column Machining Center. In 2008, we have signed a technical cooperation agreement with well-known German turning machine manufacturer A. Monforts Werkzeugmaschinen GmbH and arranged an off-site training in Monforts Germany. Starvision team integrates advanced technology and strict attitude into our own products. We set ourselves very high standards and always keep up constant know-how exchanges and innovations. These not only enhance our own technology but also strengthen our faith and passion to machine tool industry. Concentrate on the quality of our product and fulfill the needs of our customers. Our goal is, with support from world-class suppliers, making a concerted effort to offer the best Starvision Double Column Machining Center to our customers.

Starvision Machinery was founded in 2006. We might seems to be a young company, but our team carries more than 20 years of professional experience in RD, assembly, QC and marketing double column machining center. We started with cooperating with well-known German lathe manufacturer Monforts, though the project was terminated due to economic crisis in 2008. From 2009, we applied advanced technology and strict craftsmanship to our own product and developed double column machining center in both boxway and liner guideway design with the capacity from 2 to 10 meters. In addition, to answer the booming aerospace industry, we have recently released 5-axis machine as well as high speed compact one. On marketing side, our machines have been delivered to 17 countries over the world with the application from the most advanced aerospace industry to general machining and have great reputation from the customer. Our pace is fast but stable - we always concentrate on double column machining center.