請用 Wechat 掃描台灣精品QRcode 或 搜尋ID: TaiwanExcellence

Due to the COVID-19 epidemic, various industries were affected at the beginning of this year. The sale of consumer products also began to greatly fluctuate, thereby testing the crisis management abilities of affected companies. The most direct impact of the epidemic was the interruption of supply chains and the delay of Chinese factories in resuming work, thus stopping material supply. Production capacity and allocation of raw materials have been the focus of the consolidation of many Taiwanese companies recently.

Compared with companies whose production lines are all in mainland China, companies that also have production chains in Taiwan have more control over deployment capacity to weather the storm. Most Taiwanese companies have factories in both mainland China and Taiwan. Deya Hsu, the general manager of ‘deya’ — a Taiwan-based premium brand that produces environmentally-friendly functional bags from marine recycling waste — said frankly that because of limits regarding manpower, material resources, policies, and other factors, it is not easy to achieve the goal of products that are 100% made in Taiwan (MIT). We do not have world-class production capacity, and manufacturing costs in Taiwan are still higher than those in mainland China. Unlike the SARS outbreak, cities were not under lockdown at the time of the outbreak, and it did not happen at the beginning of spring when factories resumed work. Therefore, unlike what happened during the SARS epidemic, production lines did not come to a halt on a large scale. Fortunately, some of our production lines are in Taiwan which enable relatively high output control. We try our best to deliver purchased goods on time. However, even if the factory is not located in mainland China, it will inevitably be affected. If one of the parts or raw material produced in the mainland fails to arrive on schedule, production cannot be continued. Similar to the concept of data backup, manufacturers now need to think about a sustainable operation.

There are also voices in the industry stating that although this is a major challenge, it is also a critical moment to reshuffle. Some clothing manufactures stated that people are now mainly panic shopping. The willingness to buy consumer goods has generally declined, unless they are disinfection products that are necessary for livelihood. Since the beginning of spring, business performance has dropped by 50%. To sail through this adversity, it is better to maintain corporate capital for at least 3 to 5 months. Many in the industry observed that one should take the opportunity to improve brand strength, consolidate brand value, and use appropriate marketing methods to communicate with target customers in order to reduce the consumer negative perception of unavailable products and price competition. This could result in the crisis being leveraged as an opportunity to increase the fan base and grow against the trend.

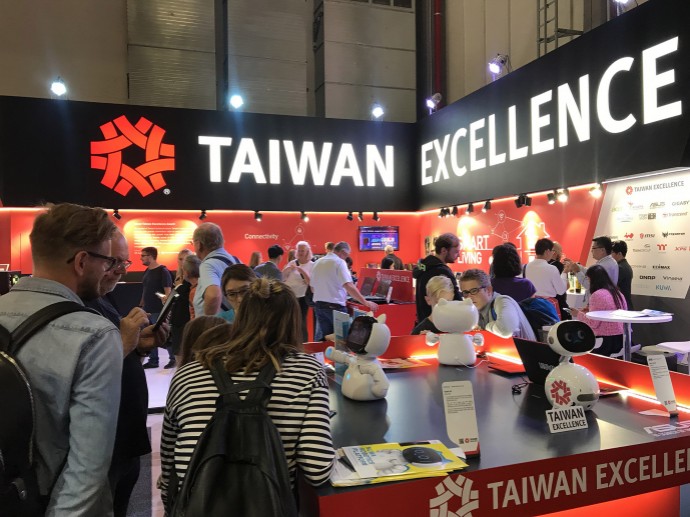

In order to strengthen the public image of Taiwanese industries, Taiwan Excellence continues to promote a high-quality image of the Taiwanese industry through cooperation with media and social platforms in various countries. This supports public perception of Taiwanese products as maintaining high-quality, reliable, and strong industrial momentum — even in the face of the coronavirus epidemic. Taiwan Excellence meets the needs of the consumer during this epidemic. Related epidemic prevention products from award-winning enterprises are promoted at home and abroad, such as Microlife’s infrared non-contact forehead temperature guns, Rice Ear’s personal air purifiers, Eleclean’s ‘electro-oxidation’ disinfection spray and Mitcorp’s ultraviolet light sterilization robot. To target international B2B customers, Taiwan Excellence may cooperate with well-known media in various countries to report the resilience and capabilities of Taiwanese companies so as to strive for international orders. Powerful even in unfavorable circumstances, Taiwan Excellence continues to provide the most innovative and high-quality products and will jointly power through this difficult period.

Liaison supervisor for this case:

CHUN-TSE, WU

Executive Director of Strategic Marketing Department, TAITRA

02-2725-5200 #1300

wuct@taitra.org.tw

Previous article

2020-03-26

Next article

2020-03-10